The secret of the EGR-certified ERGOLASTEC® workplace mat is based on the interaction of special geometry sides (surface and back of the rubber mat), which stimulate continuous compensatory movements. This means that the mats are developed in such a way that the body vibrates naturally and thus the leg and calf muscles remain permanently in easy motion. This reduces the one-sided pressure on the intervertebral discs and ensures a balanced load on the back muscles: the spine is stabilized.

Depending on the area of application, different mat surfaces are recommended:

Flat, textured surface: In dry workplaces, a flat but non-slip surface offers advantages due to the good turning ability of the foot - especially in relieving the knee area. Cleaning is usually easier than with raised geometries and it is quite possible to drive on it with light equipment.

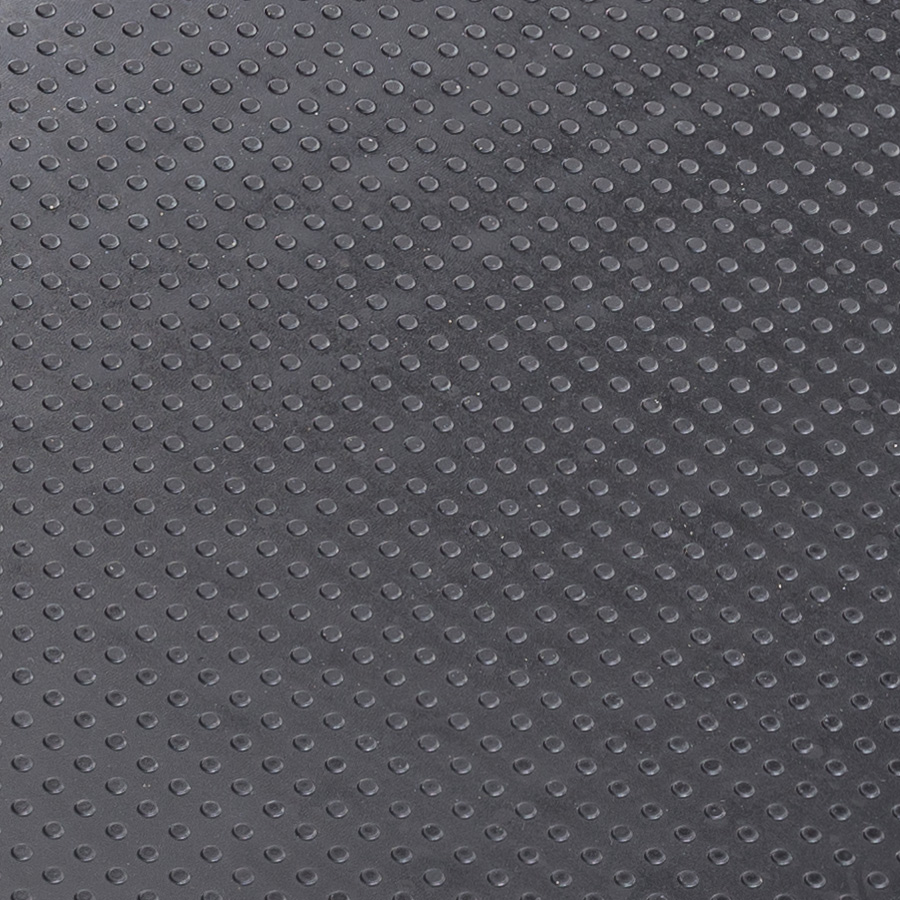

Ball knobs surface: The hemispherical studded surface (_wet) is primarily suitable for applications where chips and contamination also occur in connection with moisture. The advantage of these hemispheres, in turn, lies in the rotational relief of the knee areas when it is possible to stand or rotate over the falling media. Thus, you stand securely on the rubber hemispheres, and not on the contamination or metal chips. These mats are also often used in an oil-resistant version.

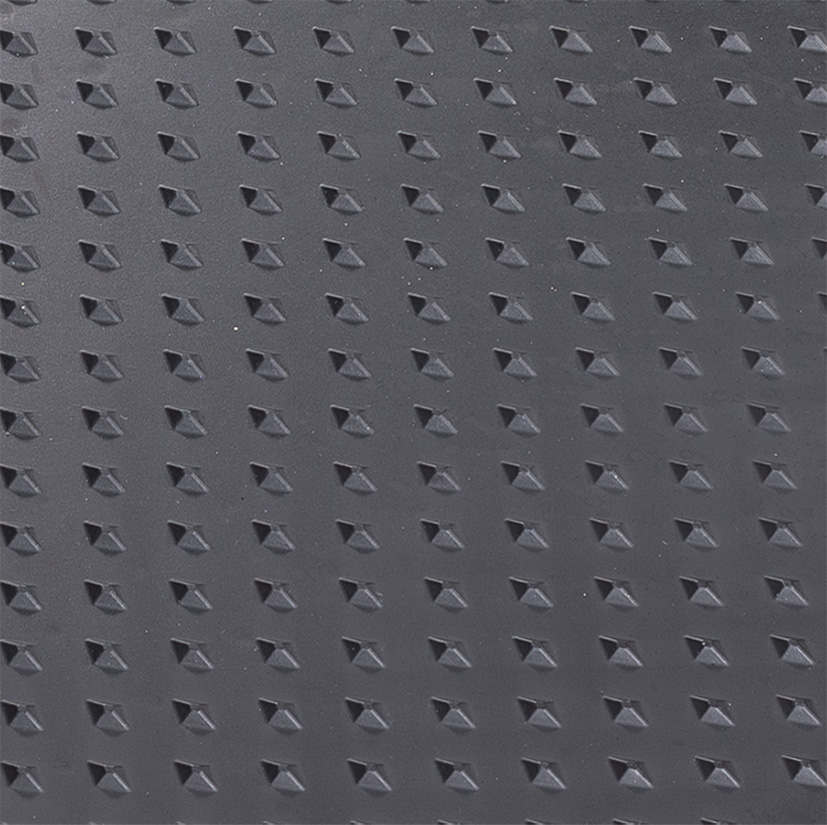

Diamond profile surface: Compared to the ball stud surface, this variant (_diamond) offers higher slip resistance on the top of the mat due to the diamond-shaped pyramids. It is also used in wet and greasy areas in front of workbenches, assembly tables, assembly lines, lathes and milling machines, grinding and welding stations. For very slippery workplaces, this surface of the oil-resistant nitrile mat is also coated with quartz sand (_oil_diamond_quarz).